How Bluetooth PCB Panels Energy the Future of Wireless Devices

How Bluetooth PCB Panels Energy the Future of Wireless Devices

Blog Article

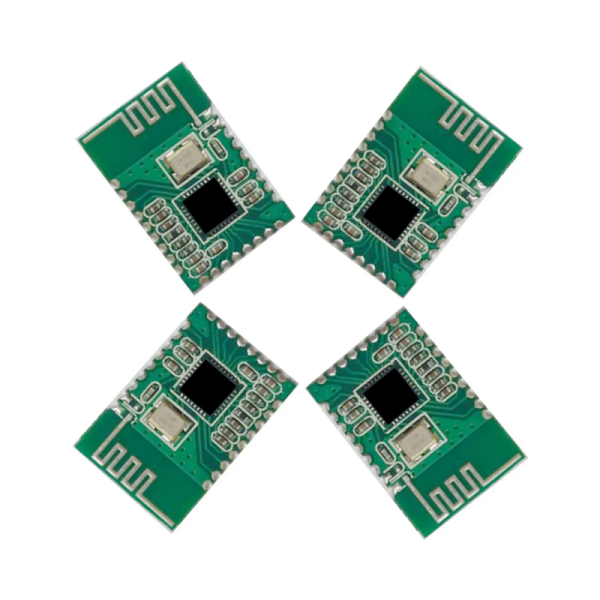

Wireless engineering has changed into a critical part of contemporary connection, allowing products to interact wirelessly across diverse industries. In the middle with this widely-used technology lies the Wireless PCB board, the motor that forces smooth communication. This blog explores the cutting-edge role of bluetooth pcb board, their significance in achieving connectivity, and the primary parts which make them function.

Why Bluetooth PCB Panels Subject

Wireless PCB (Printed Circuit Board) panels facilitate instant information sign between devices. They kind the backbone of Bluetooth-enabled techniques, from your own wireless headphones to professional IoT (Internet of Things) equipment. Their significance is based on providing a dependable, powerful software for transmission while eating small energy.

Statistics Supporting Wireless Development

Bluetooth engineering isn't merely a feature; it's becoming an international necessity. In line with the Wireless SIG Market Outlook, Bluetooth-enabled product deliveries will achieve 6.4 million annually by 2025. Among them, purposes in smart home products, healthcare, and automotive programs are quickly expanding. Wireless PCB boards offer as an important enabler of this volatile growth.

Essential The different parts of Bluetooth PCB Panels

To completely enjoy the role of Wireless PCB boards, it will help to understand their important parts and the tasks they perform:

1. Microcontroller Unit (MCU)

The MCU functions as the brain of the Bluetooth PCB. It operations data and manages transmission between devices by relaying recommendations to the Bluetooth module. High-efficiency MCUs are sought after to make certain responsiveness and low-power operation.

2. Antenna

Efficient antennas are integrated for trusted connectivity. They transfer and get radio volume signals, growing the foundation of the board's instant capabilities. Contemporary Bluetooth PCB boards often incorporate clay antennas for small design and high performance.

3. Bluetooth Module

Sitting in the middle of the table, that component determines the connection between devices. Many use variations of Wireless Reduced Energy (BLE) modules, specifically made to cut back energy use while ensuring powerful connectivity.

4. Energy Management Circuit

Power effectiveness is non-negotiable in today's linked ecosystem. These tracks guarantee the efficient usage of power from the power supply, increasing battery performance across devices like wearables or medical equipment.

5. Printed Circuit Layout

The look of the PCB structure is pivotal. Parts must be cautiously placed to avoid electromagnetic disturbance (EMI) and to improve the signal strength. A well-structured PCB format becomes the connection and efficiency of a Wireless device.

Driving the Future of Connectivity

The importance of Wireless PCB boards can not be overstated in today's tech-forward world. By developing cutting-edge components like BLE modules and efficient energy administration tracks, these boards will be the building blocks of easy instant interaction. With the surge in clever units and IoT systems, optimized PCB styles will remain required for connectivity.

Wireless PCB boards continue steadily to unlock possibilities across industries, getting billions of units deeper together. That trend of advancement is just why organizations are investing greatly in refining PCB technologies to ensure low energy consumption, robust efficiency, and reliable communication. Whether you're a tech fan or somebody employed in technology, knowledge Wireless PCB boards is essential to appreciating the backbone of modern connectivity.

Report this page